|

|

Build Your Online Product Catalogs?

| Product Name: |

Aluminum die cast with chrome finishing

|

| Supply Ability: |

|

| Related proudcts |

die casting, die casting mould, aluminum die casting, |

| Specifications |

1 |

| Price Term: |

|

| Port of loading: |

Ningbo |

| Minimum Order |

Mould: 1pc; product: 1000pcs |

| Unit Price: |

|

|

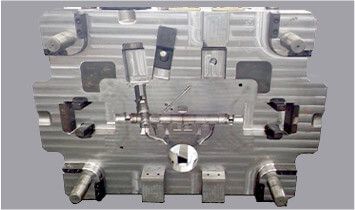

Aluminum die cast with chrome finishing chrome finishing die casting aluminum alloy die casting

Chrome finishing aluminum die casting parts is much strict technical request, particularly for super quality stand, zinc alloy parts is much easy take chrome finishing after polishing. How can we produce so nice chrome finishing parts by casting aluminum material not casting by zinc alloy? Some our customer need their products light and same cosmetic surface like zinc alloy casting parts. First step high pressure aluminum casting molds air vent size need increasing bit than normal practice. Let air have enough time escape from aluminum injection mold. possible to select brass contain rate high aluminum alloy, we suggest aluminum alloy material like ADC10. ADC11, ADC12, A380, B390, 392, for your chrome finishing parts.

Many aluminum die casting supplier will mix recycle material during casting, this is obvious wrong. Any tiny impurity mix casting material is disaster during polishing and chrome coating, in fact even melting furnace need clearing well before casting. Many die cast supplier knew basic chrome plating process. Normal practices is one layer brass coating+ one layer nickel coating +one layer chrome coating. Professional aluminum die casting co***ny will add another polishing step after one layer brass coating. in our chrome finishing die casting field we call water polishing. The polishing wheel should soft and lubrication by water during polishing.

Chrome finishing aluminum die casting parts is much strict technical request, particularly for super quality stand, zinc alloy parts is much easy take chrome finishing after polishing. How can we produce so nice chrome finishing parts by casting aluminum material not casting by zinc alloy? Some our customer need their products light and same cosmetic surface like zinc alloy casting parts. First step high pressure aluminum casting molds air vent size need increasing bit than normal practice. Let air have enough time escape from aluminum injection |

| Company: |

Ningo goal sure machining co. ,ltd

|

| Contact: |

Mr. Kavin Jin |

| Address: |

Zhejiang |

| Postcode: |

305121 |

| Tel: |

860574-83017530 |

| Fax: |

|

| E-mail: |

|

|

|

|